Professional Finishing Solutions

Built to Last, Made to Shine

Quality Rooted in Integrity, Future Driven by Innovation

Integrity is the basis for the survival and development of enterprises, MingXin company has been adhering to the integrity of the development concept since its inception, continuous innovation to improve the quality to meet the increasingly strict performance requirements, and created a well-known brand in the industry, won widespread praise.

About Us

Shanghai Mingxin Electrostatic Coating Co., Ltd., founded in 2001 and located at No. 125 Hengfei Road, Waigang Industrial Park, Jiading District, Shanghai, is a professional company specializing in sheet metal design, production, and surface coating treatment.

Its business scope covers metal sheet fabrication, degreasing, phosphating, pickling, electrophoresis, shot blasting, and powder coating, serving industries such as construction machinery, home appliances, hardware, automobiles and motorcycles, power control equipment, architectural decoration, sporting goods, medical equipment, and aluminum profiles.

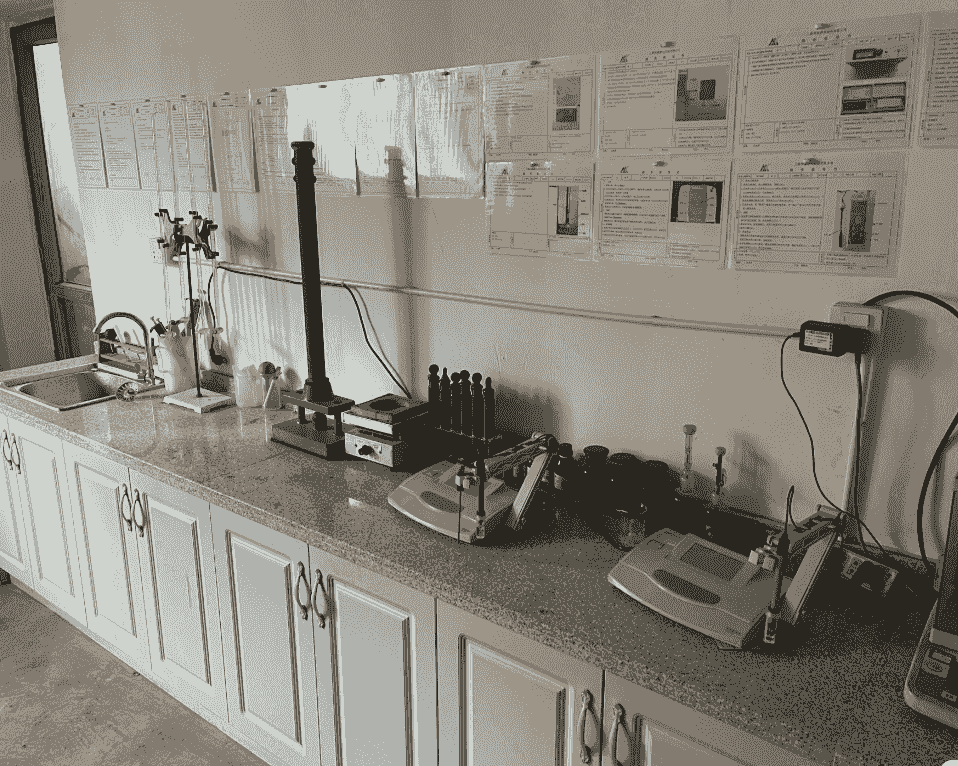

The company is equipped with a professional sheet metal processing workshop, pretreatment workshop, and powder coating workshop, holding full qualifications for pretreatment and powder coating production. With a team of first-class technical professionals, Mingxin provides specialized process and technical solutions. It is also equipped with a professional laboratory and testing instruments, capable of carrying out neutral salt spray tests, aging tests, damp-heat tests, and other standard supporting inspections.

Production Line Introduction

Pretreatment & Electrophoretic Coating Line:

Utilizes degreasing and phosphating chemical pretreatment processes combined with continuous electrophoretic coating production capacity. The business scope covers orders from industries such as construction machinery, automotive parts, and hardware appliances.Product Size Requirements:

Weight ≤ 1000 kg

Length ≤ 3 m

Width ≤ 0.8 m

Height ≤ 1.3 m

Production Capacity: 500–20,000 pieces per day

Tailor-made fixtures are designed for different types of workpieces.

Adopt a first-in, first-out system to ensure orderly production.

Conduct timely testing and precise management of pretreatment and electrophoretic bath parameters.

Pretreatment, Electrophoretic Coating, Painting & Powder Coating Gantry Line

Equipped with extra-large tanks, utilizing degreasing, de-rusting, and phosphating chemical pretreatment processes, combined with continuous electrophoretic coating, powder coating, and painting capabilities.

Business Scope: Special orders for oversized workpieces, primarily serving industries such as construction machinery, automotive, new energy, and electrical control.

Product Size Requirements:

Weight ≤ 5000 kg

Length ≤ 7 m

Width ≤ 2.6 m

Height ≤ 2.6 m

Production Capacity: 1,000–2,000 pieces per day

Programmable or manual control to ensure product quality.

Extra-large space enables fast drying of products.

Capable of customizing key parameters based on product performance requirements to ensure quality and competitiveness.

Powder Coating Line

We operate three continuous powder coating lines and one intermittent line, allowing us to design tailored production processes based on performance requirements. Currently, we support both two-coat one-bake and one-coat one-bake processes.

Our business scope covers diverse industries, including construction machinery, automotive, new energy, electrical control, and fitness equipment, meeting both standard and special-order requirements.

Product Specifications:

Weight ≤ 5000 kg

Length ≤ 7 m

Width ≤ 2.6 m

Height ≤ 2.6 m

Production capacity depends on workpiece size, with two-shift operations available.

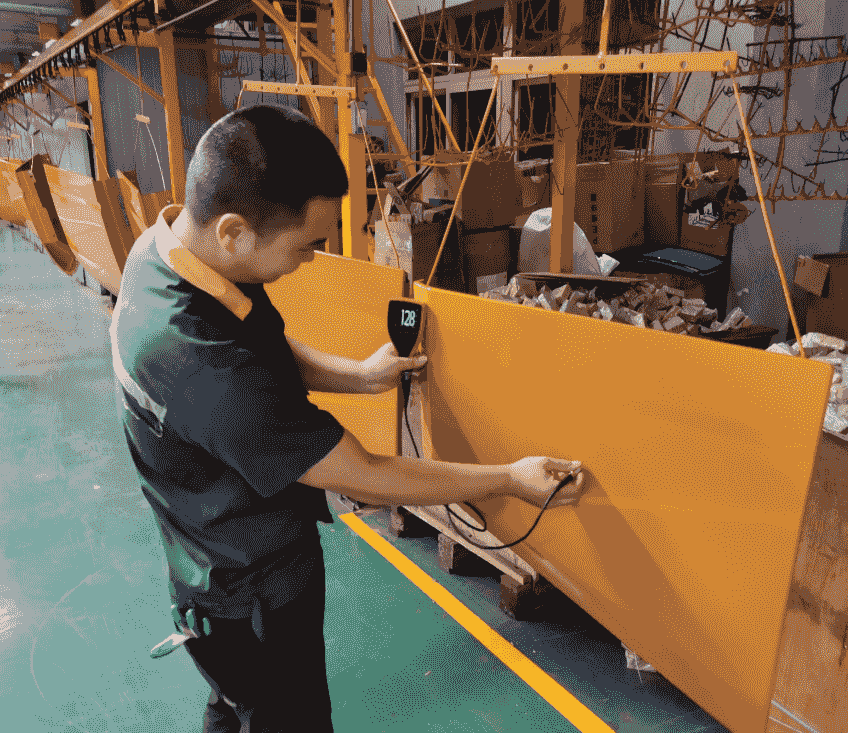

A team of highly experienced powder coating operators, capable of handling irregular and complex-shaped products.

A comprehensive quality inspection system ensures issues are identified and resolved in time, preventing defective products from leaving the factory.

Customized packaging and logistics solutions guarantee safe, damage-free transportation and minimize handling defects.

Excavator Cab Floor Panel Painting Process

This specialized line integrates blasting, electrophoresis, and advanced surface treatment to guarantee maximum durability. Through multiple cleaning and ultrafiltration stages, followed by precise drying and inspection, we achieve strong adhesion, outstanding corrosion resistance, and stable performance for cab floor panels.

Case Metal Processing and Painting Process

Our case metal coating line integrates pretreatment, electrophoresis, and powder coating in a seamless workflow. With strict quality checks and reliable process control, we deliver durable, corrosion-resistant, and high-quality finishes for a wide range of industrial applications.

Excavator Door Panel Painting Process

Designed for construction machinery components, this line combines pretreatment, electrophoresis, primer coating, and surface powder finishing. Every step is carefully monitored to ensure uniform coating, long-lasting protection, and superior appearance, fully meeting the high standards of the excavator industry.

Cooperative Partners

We are committed to earning trust through quality and innovation. With our expertise in coating and surface treatment, we have established long-term partnerships with many renowned enterprises across industries such as automotive, construction machinery, electrical equipment, and smart manufacturing.

Our partners include SAIC Motor, NIO, SANY, CHINT, Schindler, Ziehl-Abegg, and more.

These collaborations not only recognize our technical strength and service excellence but also inspire us to keep striving for higher standards.Contact Us

© 2024